Why is the Rubber Screw Barrel Important in Extrusion Machines

2025-08-15

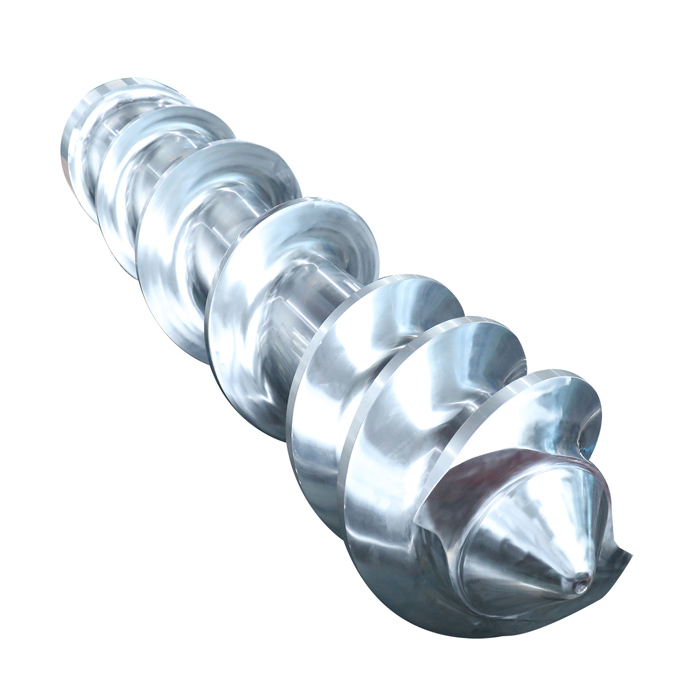

If you've worked in the extrusion industry, you know that every component matters. But have you ever wondered why the Rubber Screw Barrel stands out as one of the most critical parts of an extrusion machine? With over 20 years of experience at EJS, I’ve seen firsthand how the right Rubber Screw Barrel can make or break your production efficiency. Let’s dive into why this component is indispensable and how EJS delivers the best solutions for your extrusion needs.

What Makes the Rubber Screw Barrel a Game-Changer in Extrusion

The Rubber Screw Barrel isn’t just another part—it’s the heart of your extrusion machine. Without it, achieving consistent product quality would be nearly impossible. Here’s why:

-

Precision Mixing & Melting – The Rubber Screw Barrel ensures uniform material distribution, eliminating uneven textures.

-

Durability Under Pressure – High-quality barrels withstand extreme temperatures and friction, reducing downtime.

-

Energy Efficiency – A well-designed Rubber Screw Barrel minimizes power consumption while maximizing output.

At EJS, we engineer our barrels to exceed industry standards, ensuring your extrusion process runs smoother and longer.

How Does the Rubber Screw Barrel Impact Your Production Line

Ever faced unexpected shutdowns due to wear and tear? A subpar Rubber Screw Barrel can lead to:

✔ Frequent replacements

✔ Inconsistent product quality

✔ Higher operational costs

Our EJS Rubber Screw Barrels are crafted from premium alloys and undergo rigorous testing to prevent these issues. Check out how our specifications outperform competitors:

| Feature | Standard Barrel | EJS Rubber Screw Barrel |

|---|---|---|

| Material | Standard Steel | High-Chromium Alloy |

| Lifespan | 6-12 Months | 18-24 Months |

| Temperature Range | Up to 200°C | Up to 300°C |

| Energy Consumption | Moderate | 15% More Efficient |

What Should You Look for in a High-Performance Rubber Screw Barrel

Not all barrels are created equal. Here’s what sets EJS apart:

-

Corrosion Resistance – Our barrels resist chemical degradation, ideal for rubber and polymer extrusion.

-

Customizable Designs – Whether you need single or twin-screw configurations, we tailor solutions for your needs.

-

Smooth Internal Finish – Reduces material sticking and ensures consistent flow.

Still unsure? Our team at EJS can help you select the perfect Rubber Screw Barrel for your specific application.

Where Can You Get a Reliable Rubber Screw Barrel That Lasts

At EJS, we don’t just sell parts—we provide long-term solutions. Our Rubber Screw Barrels are trusted by manufacturers worldwide for their reliability and performance.

Why settle for less when you can have the best? Contact us today to discuss how our Rubber Screw Barrel can optimize your extrusion process. Let’s solve your production challenges together—reach out now for a customized quote!

Contact Us today and let EJS be your trusted partner in extrusion excellence.