What Are the Latest Innovations in Rubber Screw Barrel Technology

2025-08-15

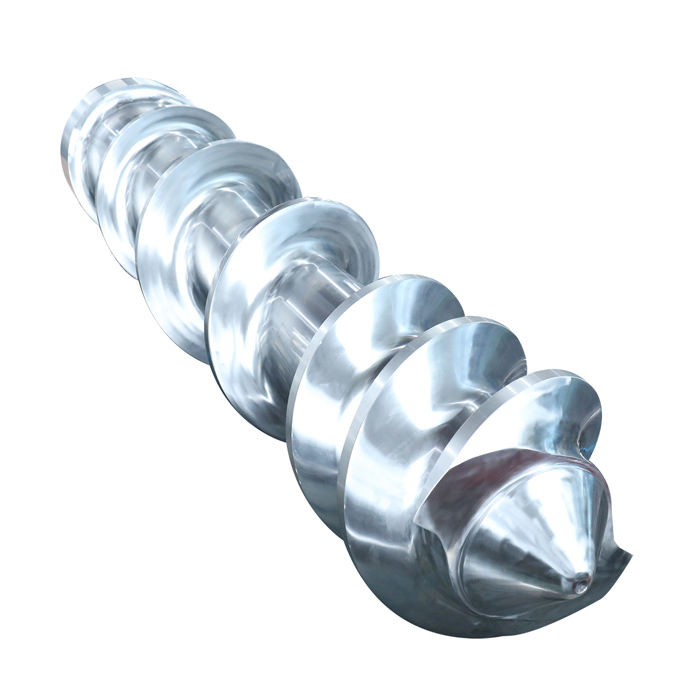

The rubber extrusion industry is evolving rapidly, and Rubber Screw Barrel technology is at the heart of this transformation. At EJS, we continuously integrate cutting-edge advancements to enhance performance, durability, and efficiency. Below, we explore the latest innovations and how they benefit your production process.

Key Innovations in Rubber Screw Barrel Technology

-

Advanced Wear-Resistant Coatings

-

New tungsten carbide (WC) and ceramic coatings significantly extend barrel lifespan.

-

Reduces friction and corrosion, ideal for high-abrasion rubber compounds.

-

-

Precision Machining for Optimal Flow

-

CNC-balanced screw design ensures uniform material mixing.

-

Minimizes energy waste and improves output consistency.

-

-

Smart Temperature Control Systems

-

Integrated PID-controlled heating zones prevent overheating.

-

Enhances rubber curing accuracy for superior product quality.

-

-

Modular Screw Designs for Versatility

-

Interchangeable screw segments allow quick adaptation for different rubber grades.

-

Reduces downtime and increases production flexibility.

-

EJS Rubber Screw Barrel – Technical Specifications

| Feature | Specification | Benefit |

|---|---|---|

| Material | Nitrided Steel / Bimetallic Alloy | Extreme wear resistance |

| L/D Ratio | 20:1 to 28:1 | Optimal rubber processing |

| Screw Diameter | 30mm – 150mm | Fits various extruder sizes |

| Heating Method | Electric or Oil Heating | Precise temperature control |

| Max. RPM | Up to 300 RPM | High-speed production capability |

Rubber Screw Barrel – FAQ Section

1. How often should a Rubber Screw Barrel be replaced?

A well-maintained EJS Rubber Screw Barrel can last 2-5 years, depending on material abrasiveness and operating conditions. Regular inspections help detect wear early.

2. What causes premature wear in Rubber Screw Barrels?

Common causes include improper temperature settings, abrasive rubber compounds, and misalignment. Using high-quality coatings and proper maintenance can mitigate these issues.

3. Can a Rubber Screw Barrel be repaired instead of replaced?

Yes, EJS offers reconditioning services for worn barrels, including re-chroming and re-machining. However, severe damage may require a full replacement for optimal performance.

Upgrade Your Rubber Extrusion with EJS

At EJS, we combine innovation, precision engineering, and industry expertise to deliver the best Rubber Screw Barrels for your needs. Whether you need higher efficiency, longer lifespan, or custom solutions, we have the right technology for you.

Contact us today for a consultation or request a quote—let’s optimize your rubber extrusion process together!