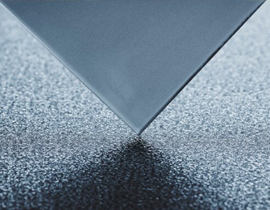

Is Scratch Resistance the secret to longer-lasting, higher-value surfaces?

2025-08-13

Scratch Resistance is more than a marketing phrase — it's a measurable property that directly affects product longevity, perceived quality, warranty costs and customer satisfaction. As an SEO professional with two decades of experience in industrial coatings and materials messaging, I'll walk you through what Scratch Resistance really means, the parameters your engineers and purchasers care about, where it matters most, and clear, actionable FAQs to help convert search traffic into qualified leads.

What is Scratch Resistance and why it matters

Scratch Resistance describes a surface's ability to withstand mechanical abrasion or penetration that leaves visible marks. For consumers and B2B buyers, better Scratch Resistance means:

-

Longer aesthetic life (fewer returns and fewer complaints).

-

Lower life-cycle costs (less need for refurbishing or replacement).

-

Improved perceived value and brand trust in premium categories (electronics, automotive trim, furniture, eyewear, appliances).

Search intent around "Scratch Resistance" often includes comparisons (which coating/system performs best), test methods, and application guidance — content that ranks well answers those questions quickly and authoritatively.

Key product specifications

Below are the core parameters buyers look for when evaluating a Scratch Resistance solution. Include these in product pages and tech datasheets to capture high-intent traffic.

Top product specs

-

Substrate compatibility: glass, plastic (PC, PMMA), metal, wood, ceramics.

-

Coating type: hardcoat, UV-cured, solvent-borne, waterborne, sol-gel.

-

Thickness: typical range 1–20 µm (application and performance dependent).

Simple product-parameter table

| Parameter | Typical Value / Range |

|---|---|

| Coating Type | UV-cured hardcoat / sol-gel |

| Thickness | 1 – 20 µm |

| Pencil Hardness | H – 9H (depending on formulation) |

| Taber Abrasion | 100–2000 cycles (depending on grade) |

| Adhesion (cross-cut) | 0 – 1 (ISO scale) |

| Haze | <1% (optical grades) |

| Cure | UV cure: seconds; thermal: minutes–hours |

| Recommended Substrates | PC, PMMA, glass, aluminum |

Including a small, clear table like this on product pages answers scanning users and improves on-page SEO by matching purchase-intent queries.

Practical applications, testing and maintenance

Applications that most benefit from Scratch Resistance:

-

Consumer electronics screens and bezels

-

Automotive interior trim and exterior protective films

-

Optical lenses and eyewear

-

Luxury furniture and decorative laminates

-

Industrial equipment panels and medical devices

Scratch Resistance — FAQ

Q: Scratch Resistance — What standardized tests prove a coating's scratch performance?

A: Taber abrasion (ASTM D1044/ISO 9352), pencil hardness (ASTM D3363) and instrumented nanoindentation are commonly cited; combining lab metrics with real-world abrasion simulations gives the most reliable proof.

Q: Scratch Resistance — How much thickness is needed for effective protection?

A: Effective thickness depends on substrate and application; optical hardcoats often perform at 1–5 µm while heavy-wear industrial coatings may require 10–20 µm — performance scales with chemistry and cure, not thickness alone.

Q: Scratch Resistance — Can scratch-resistant coatings be applied to plastics and glass with equal success?

A: Yes, but surface energy and adhesion prep differ; plastics often need corona or plasma treatment and primer layers, whereas glass typically bonds directly with sol-gel or silane-based systems.

Final note and contact

If you need sample datasheets, Taber/pencil-test reports, or help creating product pages and FAQ schema optimized for "Scratch Resistance" queries, contact Zhongshan Qianyou Chemical Materials Co., Ltd. for technical support and samples.