How to Maintain and Extend the Life of a Plastic Injection Mould

2025-08-18

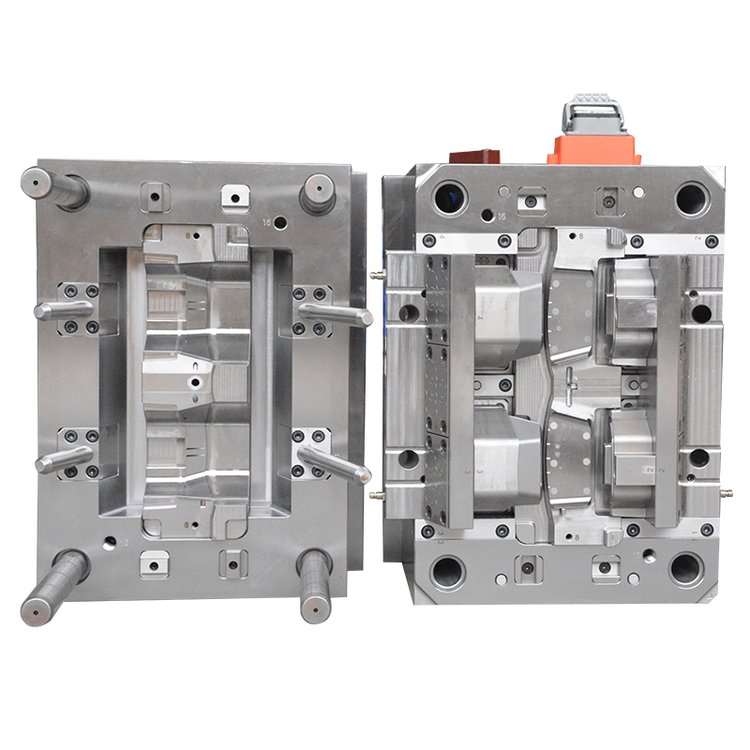

A well-maintained Plastic Injection Mould can last for millions of cycles, reducing downtime and production costs. At Sunbright, we specialize in high-performance moulds designed for longevity. Here’s how to keep yours in top condition—and why our solutions stand out.

What Are the Key Maintenance Practices for Plastic Injection Moulds?

1. Regular Cleaning and Inspection

-

Why? Residue buildup causes defects like flash and sticking.

-

How? Use non-abrasive cleaners and inspect for wear after each run.

2. Proper Lubrication

-

Why? Reduces friction and prevents premature wear.

-

How? Apply mould-release agents sparingly to avoid residue.

3. Temperature Control

-

Why? Overheating warps the mould; inconsistent cooling causes defects.

-

How? Monitor cooling channels and use high-quality thermal regulators.

4. Storage Conditions

-

Why? Humidity and dust corrode or damage critical components.

-

How? Store in a dry, temperature-controlled environment with protective coatings.

Sunbright’s Durable Plastic Injection Moulds – Built to Last

Our moulds outperform competitors thanks to superior engineering:

| Feature | Sunbright Standard | Industry Average |

|---|---|---|

| Mould Steel | Premium H13 Tool Steel | Standard P20 Steel |

| Surface Hardness | 48-52 HRC | 28-32 HRC |

| Cooling Efficiency | Conformal Channels | Traditional Drilling |

| Cycle Lifespan | 1M+ Cycles | 500K Cycles |

Why Choose Sunbright?

✔ Extended Lifespan – Precision machining reduces wear.

✔ Faster Cycles – Optimized cooling cuts production time.

✔ Lower Maintenance – Corrosion-resistant materials minimize upkeep.

Plastic Injection Mould FAQ – Solved by Sunbright

Q: How often should I perform deep maintenance on my Plastic Injection Mould?

A: Every 50,000 cycles or quarterly—whichever comes first. Check ejector pins, slides, and alignment.

Q: Can a worn-out Plastic Injection Mould be repaired?

A: Yes! Sunbright offers reconditioning services like re-hardening and polishing to restore performance.

Q: What’s the biggest mistake that shortens mould life?

A: Skipping minor repairs. Small issues (e.g., stuck ejectors) escalate into costly damage if ignored.

Need a Long-Lasting Plastic Injection Mould?

At Sunbright, we engineer moulds that endure harsh production demands while minimizing maintenance.

Contact us today for a mould that maximizes uptime and ROI!